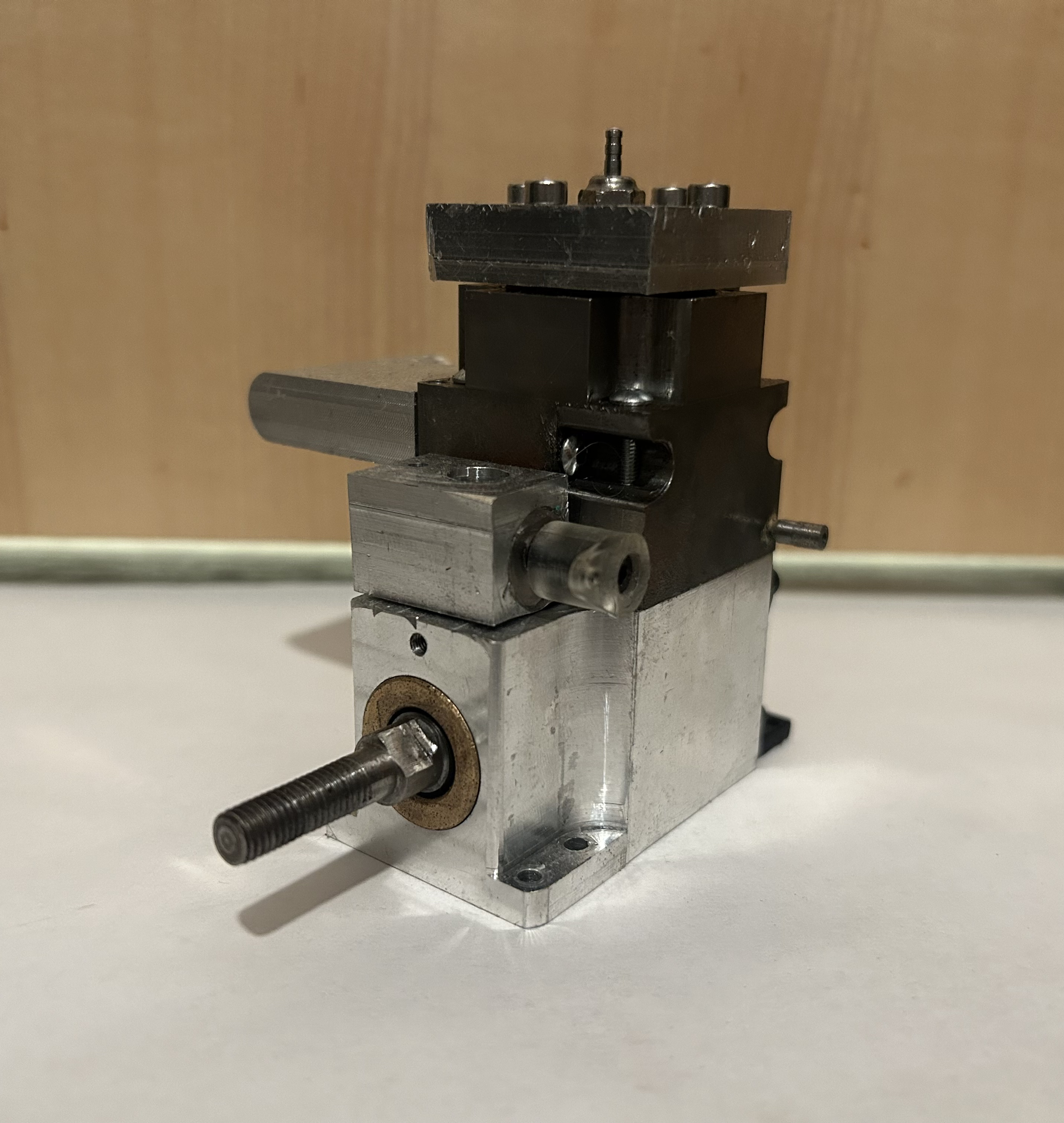

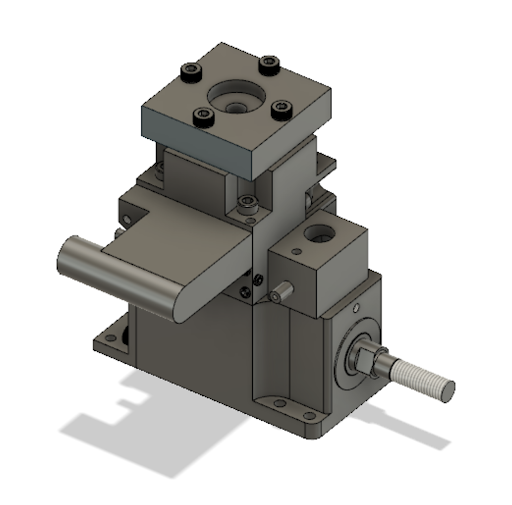

The internal combustion was made in an informal class that offered mentorship while machining. This is a single-piston combustion engine. It was machined on manual mills and lathes with the prototrack feature. The CAM was completed on fusion. I was responsible for the entire process of going from CAM to fully machined engine. After uploading the CAM to the mill, I created a tool table, calibrated every tool to the proper height, and centered the machine to my part. It was finished over the course of four weeks, working in the machine shop six hours a day.

Without a grinder available for use, I had to make the piston three times, since its necessary resolution was smaller than the resolution offered by a prototrack lathe. The final product was able to run at 5000 rpm. This was an incredible experience, not only because I am more comfortable in the machine shop, but I am better prepared to design for manufacturing.